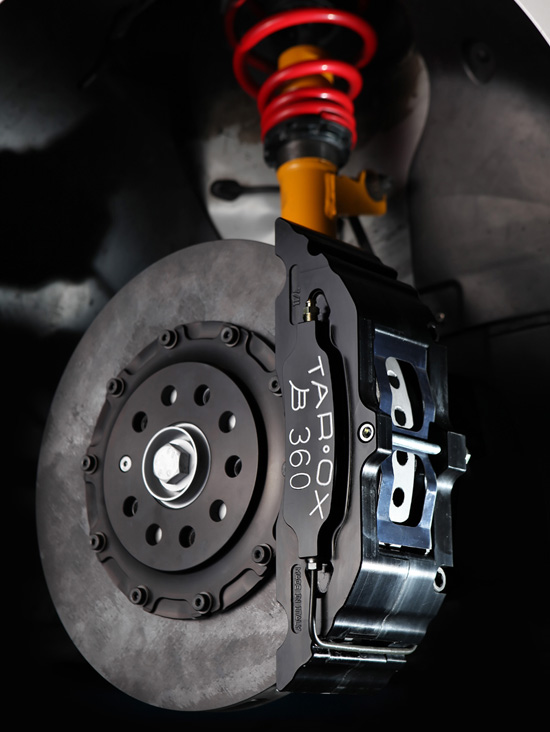

Tarox releases Carbon Ceramic Braking Range

Italian brake manufacturer Tarox has just announced the launch of its extensive Carbon Ceramic ultra-high performance braking range. The new discs draw heavily on Tarox’s extensive motorsport experience – which goes all the way up to F1 level.

The new parts are aimed at two markets. Firstly, as superior performing, cost-effective replacements for vehicles that were factory fitted with CC discs, and secondly, to be combined with Tarox calipers as the ultimate motorsport fitment for teams looking for unparalled performance combined with extended durability and heat handling capability.

TAROX Carbon Ceramic brakes offer significantly greater retardation over a wide heat range, thanks to their unique construction. The discs feature a continuous monolithic fibre structure which avoids the need of a specified layer of friction material. This construction method provides a far stronger disc structure as well as offering the added benefit that the disc can be resurfaced and reused.

Most commercially available carbon ceramic discs are of a two part moulded cut fibre structure featuring a ‘core’ and a ‘friction surface’. The core is usually a lesser material with typically, a 0.5mm bonded layer of friction material bonded on top.

However, the continuous fibre monolithic structure of the TAROX carbon ceramic discs equates to a higher thermal conductivity, allowing the brake rotor to achieve lower bulk temperatures during a braking application. The cooler running temperatures directly lower the oxidation rate of the disc improving its lifespan. This also benefits the lifespan of the brake pad.

The rate of wear on Carbon Ceramic discs is determined by oxidation – a process that occurs at high temperature when the rotor is exposed to the air around it. Oxidation levels are measured in terms of weight loss and surface texture. The disc surface will begin to feel rough with the onset of oxidation.

Due to the superior design structure, when compared to a typical composite ceramic disc the TAROX discs are 43% stronger when destruction tested back to back.

TAROX Carbon Ceramic disc 23.7 kJ of energy required @ 7400 rpm (560mph)

Typical Carbon Ceramic disc 16.6 kJ of energy required @ 6250 rpm (470mph)

TAROX Carbon Ceramic discs have been dyno tested against typical ceramic discs to monitor deterioration at key temperature ranges. The following figures show a comparison;

TAROX Carbon Ceramic disc 4 hour cycle @ 900 °C resulted in a 12.5% loss of weight

Typical Carbon Ceramic disc 4 hour cycle @ 900 °C resulted in a 19 % loss of weight

TAROX Carbon Ceramic disc 4 hour cycle @ 700 °C resulted in a 7.5% loss of weight

Typical Carbon Ceramic disc 4 hour cycle @ 700 °C resulted in a 15% loss of weight

The range launches with 23 fitments, covering outside diameters from 283mm right up to 420mm and features a wide range of thicknesses from 26mm to 40mm. In other words, almost all commercially required sizes.

Welcome to Audi Tuning Mag – one of the world’s leading blog and complete internet source for owners and enthusiasts of Audi tuning and modified cars. Audi Tuning Mag keeps you up-to-date on the latest developments in the Audi tuning scene from across the world.

Welcome to Audi Tuning Mag – one of the world’s leading blog and complete internet source for owners and enthusiasts of Audi tuning and modified cars. Audi Tuning Mag keeps you up-to-date on the latest developments in the Audi tuning scene from across the world.